Learn More

Learn More

and supplier of extraction systems for dust and fumes.

With over 34 years of experience.

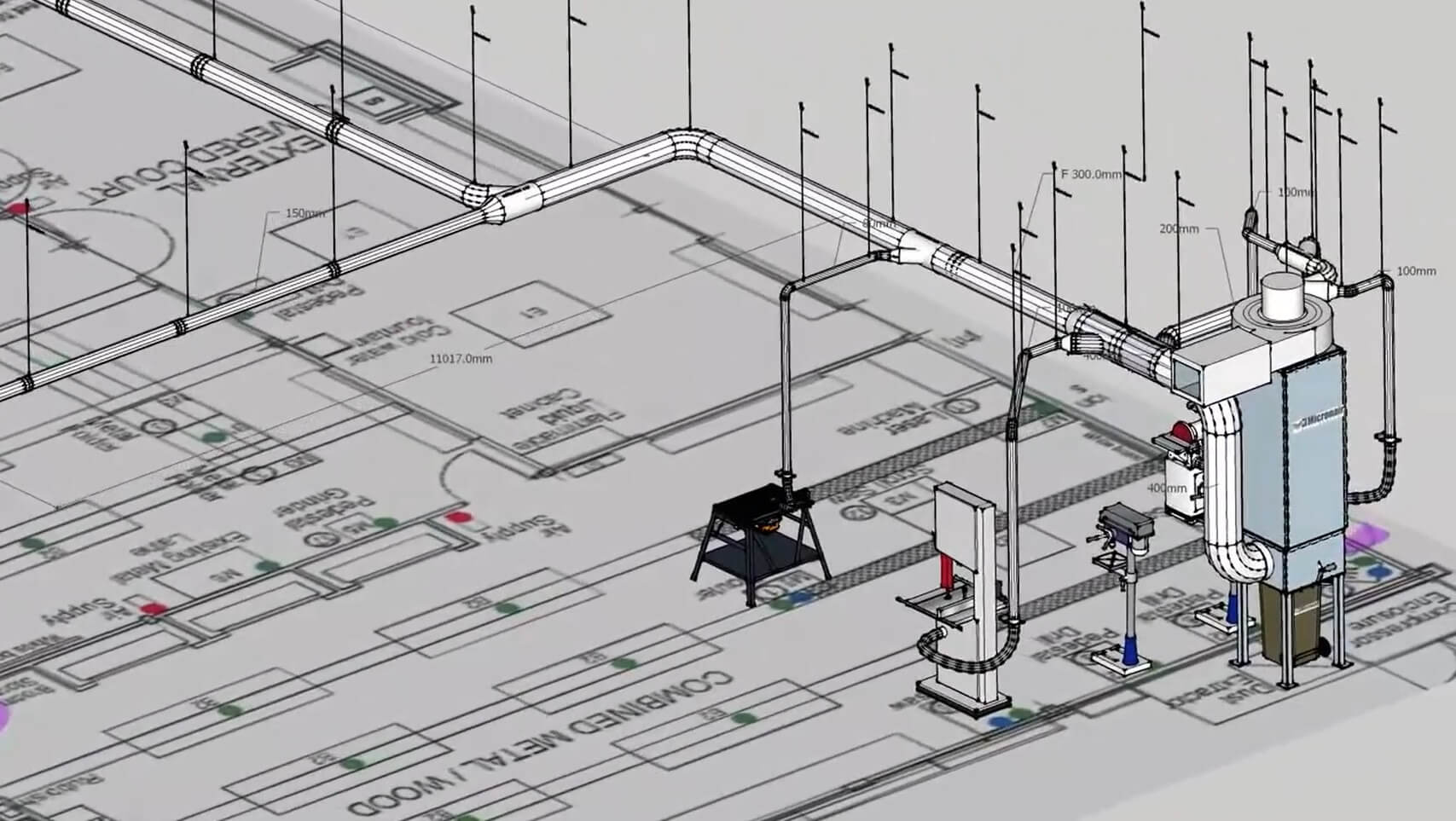

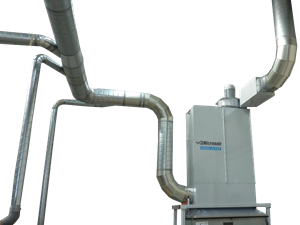

Extraction systems for dust and fume requirements

Contact us today

Dust Extraction

From woodworking to stone cutting and more, mitigating the risk of airborne particles and silica dust is crucial for employee health and safety, in addition to addressing the growing demand that comes with todays high-tech machinery in the workplace.

Fume Extraction

Managing a safe working environment from fumes, gases and the presence of chemicals with fume extraction systems manufactured to Australia Standards.

Fire & Explosion

With the implementation of spark detection and suppression systems, you not only reduce the risk of explosions but also minimize the chances of a fire starting or spreading within the extraction system.

Extraction Systems For Your Industry

WHO IS MICRONAIR

MADE IN AUSTRALIA

MADE TO ORDER

MICRONAIR DIFFERENCE

WHO IS MICRONAIR?

MADE IN AUSTRALIA

MADE TO ORDER

MICRONAIR DIFFERENCE

Testimonials

Micronair quoted, procured and installed better and quicker than any other company we could get in contact with. The boys turned up when they said and installed our new extractor whilst keeping in consistent contact with us suggesting and modifying the system as they went so it would work as efficiently as possible without interfering with existing machinery. Great job and a quality extractor.

Graham DonaldsonuiikWe have recently upgraded/replaced our dust extraction system. After careful consideration of quotes from 3 companies, we chose Micronair for our project. Don and his team have been prompt and professional at every stage, from the initial meeting to discuss our requirments through to completion of the installation. Their quote was competitive and the service spot on.

Peter Van, Everist TimberGreat lads to work with! no messing around, straight talking! Stayed back until after 12AM to finish the job without any complaints! I would defiantly recommend Clint and Shannon to deal with!!!

Shannon McNish TivnanWhat a great company! I researched an outside dust extraction unit for a small school I am working at and found Micronair, a local company, who listened to my needs and provided a very transparent quotation after visiting my worksite to confirm my needs. The staff were really switched on with getting back to me, answering any questions I had before the ordering process. The unit was installed professionally and with minimal fuss within the agreed time frame. After-sales service has also been exceptional.

Ben ThomasI’m very pleased with the performance of your team member at our plant. They exhibit great skill and professionalism, and we look forward to continuing to use your services for our equipment. Your team is doing an outstanding job, and we’re grateful for that.

Salem Al-KhanbashiThe Micron Air team, are always willing to be part of our process, Permit to Works, and SWMS, are always completed which are our safety actions. Great team.

George Western FoodsJosh from Micronair did a fantastic job installing our new dust extractor. And the system is going great. Thank you.

Jeremy, Middleton Design